The steel used in free reed instruments is not the average type of steel. It is specially produced for this industry and has unique properties (flexibility, hardness, evenness, etc.).

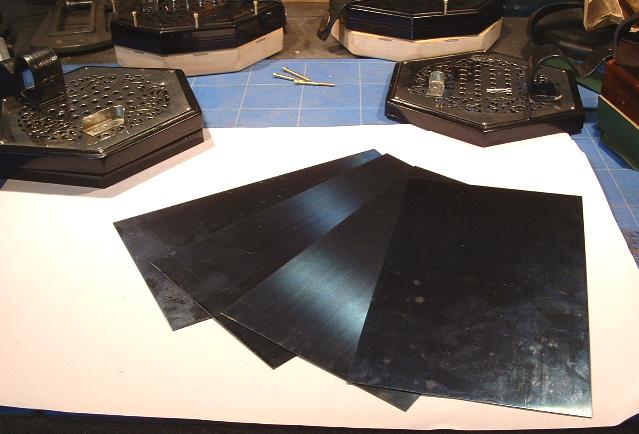

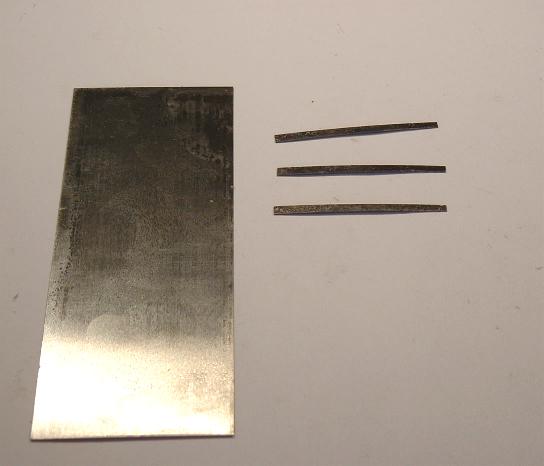

the 'raw' material

the first step, cutting it to the appropriate width

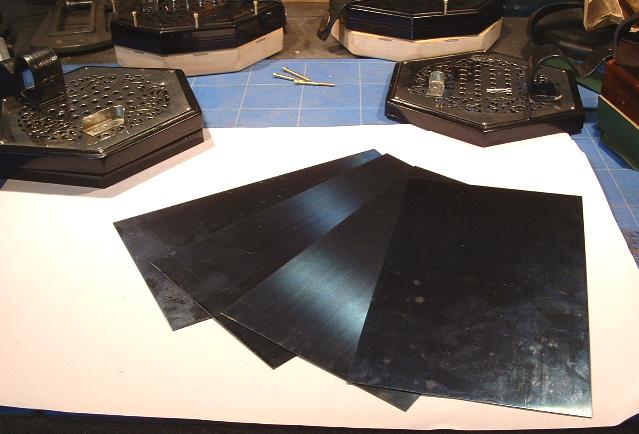

Grinding the steel to the correct thickness.

We use 4 different basic

degrees of thickness in an anglo with long scale reeds. The grinding

accuracy is 0.01mm/0.00039". The final reed curve is filed by hand.

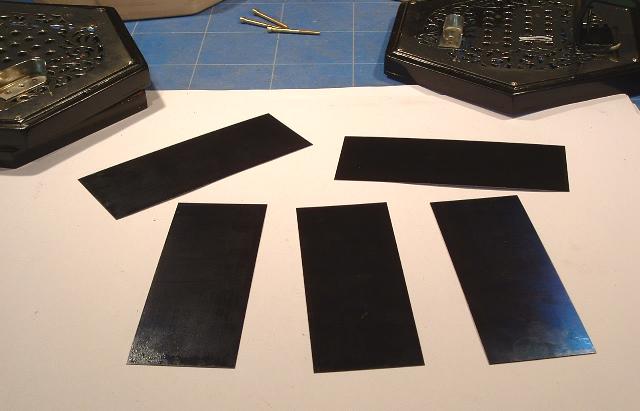

Newly cut reeds. Our reed cutting

machine is custom made. The

extreme accuracy of this machine guarantees perfect fitting reeds.

High accuracy comes at a price...one of these machines costs as

much as a nice car....at this moment we have 2 of these

machines in operation.

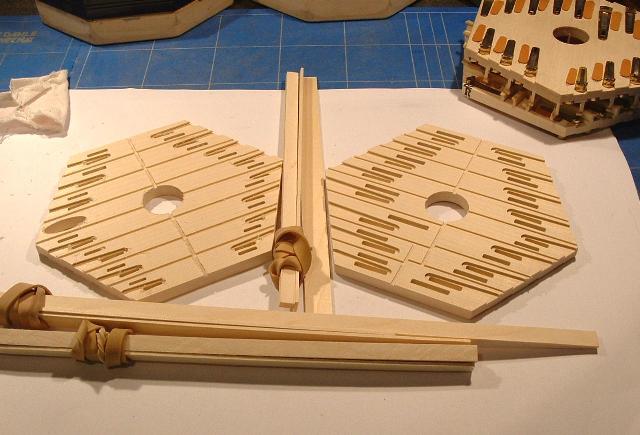

The newly made reedpans and deviders. In the

back ground

a completed set of reedpans, also for a 30 key anglo.

The end are finished, ready to be built up....

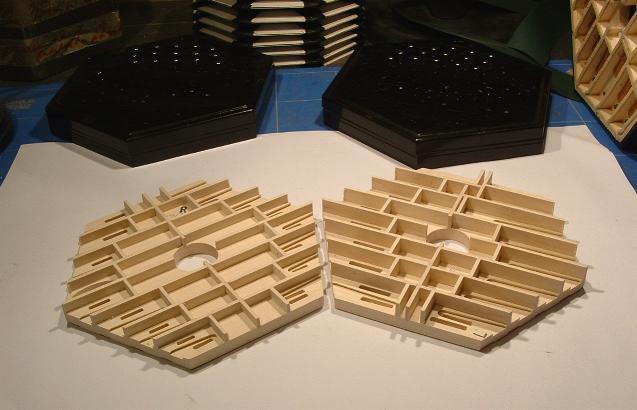

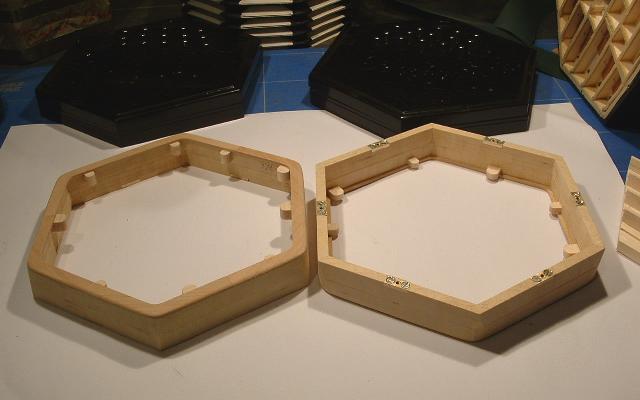

Time to finish the reedpans, bellows frames, and reed frames.

reedpans with dividers installed

bellows frames with bellows guide and blocks

reedpans in bellows frames (before chamois gaskets are installed)

Reed frame parts: frame, clamp and screws

reed frames assembled