|

The Action and

Pads

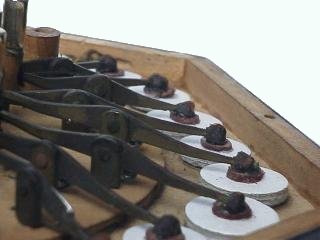

This

is the typical condition of concertina pads in older instruments. At first sight

it just looks dirty,

but when you examine the pads more closely, you'll notice

the felt is partly deteriorated.

A pad consists of a card board, felt and leather sandwich. The (leather) disk,

on top of the pad, is

connected to the leather bead, which is screwed on the

(brass) arm.

The bead/disk connection is flexible and adjusts the seating of the pad.

The oxidation on the riveted brass action (this is a Wheatstone) will interfere

with movement of the

lever.

Left

old, right new pad. Notice the difference in size. The felt in the old pad has

deteriorated.

You can even see a hole in the side. Sometimes you can spot worn

pads without having to open

the instrument by checking the key height. Uneven

key height can be a sign of deteriorated pads.

This is a view of the same instrument, but with new pads and oxidation free

action.

A 48 key concertina has the same number of pads, varying in size from about 11

mm for the high

notes to 24 mm or more for the lowest notes, depending on the

type of instrument.

The lower the note, the bigger the air hole needs to be to supply enough air.

The amount of travel

of the key when it is pushed down, determines how high the

pad will lift of the board. If the key travel

is too little, the reeds

(especially the lower ones) will not get enough air to vibrate fully. As a

result the

reed will be slow to speak and will have little or no harmonic

spectrum.

This

view shows the action, springs and keys with the (black) key base circle and

peg hole bushings.

Springs used to be made out of brass.

In this picture you can clearly see the oxidation on the springs. Old springs

can create a lot of problems.

Because brass looses its strength, brass springs

can easily break, causing a note to constantly sound.

In this instrument all the bushing and springs will have to be replaced, and the

action and keys polished.

This

shows the finished action. Although we sometimes still use brass for our

springs, we prefer steel.

The advantage of steel springs is that you can adjust the key pressure much more

accurate. They will

also keep the pressure constant much longer.

The height of the keys has a lot of influence on the sound quality of the

instrument. When the reeds

get the air they need, even brass reeds can sound

loud and and fast.

We set our action to 60-70 grams of key pressure and key travel somewhere

between 3.2mm and 4.0 mm,

depending make, age and type of concertina.

Rebuilding an action on a standard 48 key English means in parts: 48 pads, 48

springs, 48 leather beads

and disks, 48 key hole bushings, 48 peg hole bushings,

96 key base circles. All parts have to be hand made,

to the original

specifications.

Back

|